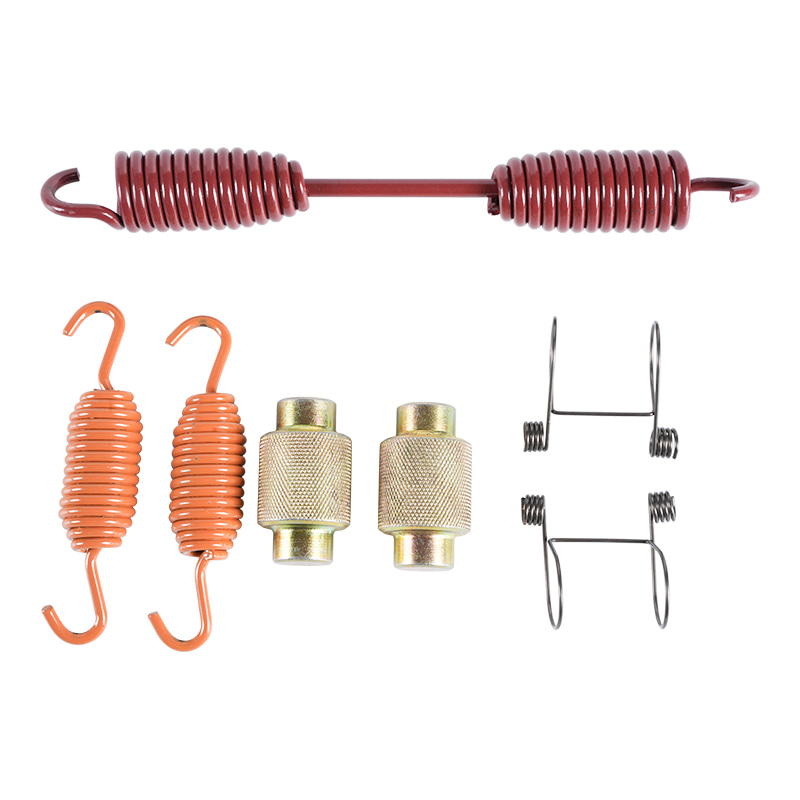

Enhance your braking system with the BPW 300*200 American Brake Shoe Assembly, engineered for precision and durability. Designed to meet high standards of performance, this brake shoe assembly is an ideal solution for reliable and effective braking.

Dimensions: 300mm x 200mm, tailored to fit a variety of braking systems.

High-Quality Materials: Constructed from premium materials for exceptional strength and longevity.

Precision Engineering: Ensures a perfect fit and reliable performance under demanding conditions.

Compatibility: Designed to meet American brake standards, making it a versatile choice for various applications.

Whether you're upgrading existing systems or outfitting new ones, the BPW 300*200 American Brake Shoe Assembly offers superior performance and peace of mind. Invest in safety and efficiency with this top-tier brake shoe assembly.

About

Zhejiang Langrun Auto Parts Co., Ltd.

The company is located in the Yangtze River Delta Cooperation Demonstration Zone (Huzhou) in Anji, Zhejiang Province, surrounded by green mountains and clear waters. It is an BPW 300*200 European Brake Shoe Assembly manufacturer and factory in China, specializing in producing heavy-duty truck and trailer brake shoes, asbestos-free brake shoe linings, and brake shoe assemblies. we can offer OEM BPW 300*200 European Brake Shoe Assembly.

The company's new plant will be completed by the end of 2023, covering an area of 29 acres, a construction area of more than 35,000 square meters, a total investment of more than 90 million yuan, an annual output of 2 million sets of brake shoes and assemblies, and more than 50 employees.

Since 2010, the company has focused on researching and developing stamping and welding brake shoe series products, with heavy-duty trucks, semi-trailers, and engineering vehicle brake shoes as its core products. It is an important production base for heavy-duty truck brake shoes in China. The company's customers are mainly concentrated in heavy-duty vehicle manufacturers and major supporting axle factories. The products are widely used in Meritor axles, BPW axles, Fuhua axles, EATON axles, etc., focusing on European and American countries. After years of experience accumulation, we already have a professional development team and mature production technology and have domestic first-class advanced equipment and precision testing equipment to ensure the stability of the entire process of the product and ensure the quality of the product. It has passed the American standard bench test and the relevant standard test of the domestic automobile industry and meets the European and American import standards.

The company has now become a modern truck brake shoe production enterprise integrating R&D, production, sales, support, and service. Because of its focus, it is professional, with stable quality, reliable reputation, emphasis on innovation, leading technology, and creating a first-class brake shoe production base is our constant pursuit.

Zhejiang Langrun sincerely welcomes new and old customers to visit the company and work with you for a win-win situation.

News

Product Knowledge

Performance characteristics of BPW 300*200 European brake shoe assembly and its application in heavy-duty trucks

In heavy-duty truck applications, the performance of the brake system is directly related to driving safety and transportation efficiency. The BPW 300200 brake shoe assembly uses advanced materials and manufacturing processes to maintain stable braking effects under high loads, high speeds and extreme weather conditions. Compared with traditional brake shoes, this European brake shoe has a lower wear rate and longer service life, which not only reduces the maintenance cost of the vehicle, but also improves the overall operating efficiency of heavy-duty trucks. In addition, the low-noise design of the BPW 300200 brake shoe significantly reduces the noise generated by the vehicle during braking, thereby improving driving comfort, especially for urban transportation and long-distance transportation.

One of the core advantages of the BPW 300*200 European brake shoe assembly is its excellent high-temperature stability. Since heavy-duty trucks often need to work under extreme temperature conditions, the brake system is very likely to overheat during long-term continuous braking, which will lead to a decrease in braking effect and even affect safety. The BPW 300200 brake shoe is made of high-temperature stable materials. Even under long-term braking, it can still maintain high braking performance, ensuring that the vehicle can complete the task safely. This feature makes it widely used in the European and American markets, especially in heavy-duty and long-distance transportation environments.

We are well aware of the advantages of the BPW 300200 European brake shoe assembly. Our products focus on providing customized solutions to meet the unique needs of different customers for brake systems. Whether it is for high-load transportation, use in extreme climate environments, or the need for high stability and low noise, the BPW 300200 brake shoe assembly can provide excellent performance. Through strict quality control and sophisticated testing equipment, we ensure the reliability and stability of each set of brake shoes, always stand at the forefront of the industry, and help the safety and development of the heavy truck industry.

How to detect the wear of the BPW300*200 European brake shoe assembly and replace it in time

As the core component of the brake system of heavy trucks and semi-trailers, the normal operation of the BPW 300*200 European brake shoe assembly is directly related to the driving safety and braking performance of the vehicle. Regular inspection of brake shoe wear and timely replacement are important steps to ensure that the brake system is always in the best condition. Since the brake shoe is constantly subjected to friction during use, its wear will gradually increase with the operation of the vehicle. If it is not inspected and replaced in time, it may lead to a decline in brake performance or even brake failure.

First, the wear of the BPW 300*200 European brake shoe is mainly checked by observing the thickness of the brake shoe. Usually, after reaching a certain degree of wear, the surface thickness of the brake shoe will be significantly reduced, and then it needs to be replaced. In order to ensure the safety of the brake system, the manufacturer usually specifies a minimum thickness standard. When the thickness of the brake shoe is lower than this standard, it must be replaced in time. For the BPW 300200 brake shoe, its high temperature stability and wear resistance make it show a long service life during use. However, under heavy load and high frequency use, regular inspection is still required to ensure that the brake shoe does not exceed the wear limit.

Secondly, in addition to detecting wear by thickness, another important inspection method is to observe the wear uniformity of the brake shoe. If the brake shoes are unevenly worn, there may be a problem with the brake system, such as an uneven brake disc or an unbalanced brake system. This situation will not only affect the braking effect, but may also cause poor contact between the brake pad and the brake disc, thereby aggravating the wear. Therefore, it is also very important to regularly check the uniform wear of the brake shoes. In this regard, the BPW 300*200 brake shoes are made of high-performance materials and precision manufacturing processes, and their wear resistance is better than many similar products. Therefore, under normal use conditions, the wear is relatively uniform and the service life is relatively long.

In addition, it is also very important to regularly check whether the brake shoes have cracks, fragments or other damage. Especially after a long period of high-temperature braking or extreme driving environment, the brake shoes may crack or fall off, which will greatly reduce the safety of the brake system. For the BPW 300*200 brake shoes, due to their excellent high-temperature stability and strength, they can maintain stable performance under extreme conditions. However, regular inspections are still required according to actual conditions.

In order to ensure the best working condition of the BPW 300*200 brake shoe assembly, it is crucial to replace the brake shoes that are severely worn in time. Excessively worn brake shoes will not only reduce the braking effect, but may also cause damage to the brake disc, thereby increasing maintenance costs. As a supplier of BPW 300*200 brake shoes, our products are ensured to be stable and durable through strict quality control and advanced manufacturing technology. Through regular inspection and timely replacement, customers can maximize the service life of the brake system and improve the safety and operating efficiency of the vehicle.

Eng

Eng  中文简体

中文简体